SuperDry-M: Reliable Moisture Control for Painting and CNC Machining Applications

- Nov 12, 2025

- 3 min read

Compressed air is vital to industrial processes, powering pneumatic tools, atomizing paint, and keeping precision systems clean. Yet, moisture in compressed air remains a silent threat. Even small amounts of water vapor can cause corrosion, surface defects, or dimensional inaccuracies, compromising product quality.

The SuperDry-M membrane dryer from PHILOS was engineered to solve this challenge, providing a compact, energy-free, and maintenance-free solution for continuous moisture removal. Below, we explore two key applications where dry, reliable air is critical: painting and coating systems and CNC machining centers.

Dry Air Importance in Painting and Coating Lines

In automotive, furniture, or industrial paint shops, compressed air is used to atomize coatings and propel them through spray guns or robotic applicators. Any trace of moisture can ruin the finish, causing blistering, pinholes, poor adhesion, or uneven gloss. Moisture in the dry air line can also introduce oil-water aerosols and contaminants, compromising color consistency.

Typical Air Requirements

Operating Pressure: 6–8 bar

Required Dew Point: ≤ –25 °C (ideally –30 °C for controlled environments)

Flow Rate: 300–800 Nm³/h for mid-scale coating booths

Air Quality: ISO 8573-1 Class 1–2–1 (oil- and particle-free, very low moisture)

How SuperDry-M Improves Coating Quality

SuperDry-M uses a proprietary hollow-fiber membrane with selective permeation. Water vapor diffuses rapidly through the membrane walls, while dry air continues downstream. A small fraction of the dry air (purge air) sweeps out the moisture continuously, with no moving parts and no electrical power.

Installed downstream of filtration units, the SuperDry-M maintains a steady dew point even during pressure fluctuations or high-demand cycles, ensuring that atomizing air remains perfectly dry. The result: uniform coatings, improved adhesion, and reduced rework.

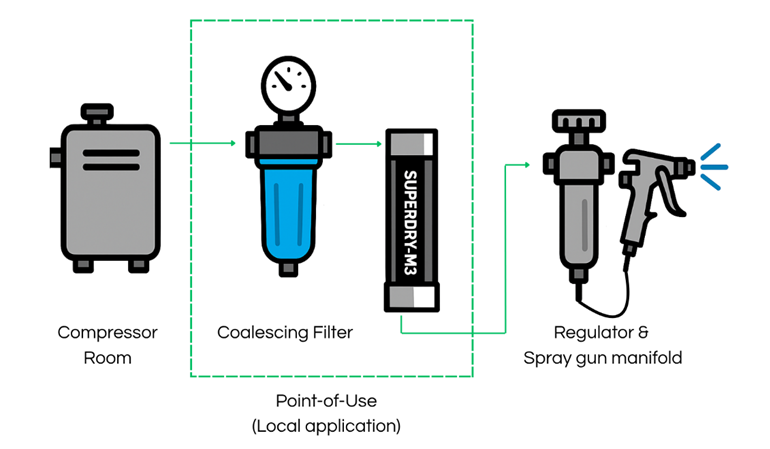

Image 1. Typical Configuration for a Painting & Coating System

The Moisture Problem in CNC Machining and Precision Manufacturing

In CNC machining centers, compressed air is used for spindle cooling, chip removal, pneumatic actuation, and part cleaning. Moist air can lead to oxidation of precision components, corrosion inside pneumatic valves, and even unstable tool performance due to water accumulation in lines or actuators. Over time, this results in higher maintenance costs and lower machining accuracy.

Air Requirements

Operating Pressure: 6–10 bar

Required Dew Point: –20 °C to –40 °C depending on material sensitivity

Flow Rate: 100–500 Nm³/h for typical CNC clusters

Air Quality: ISO 8573-1 Class 2–3–1

Why Choose SuperDry-M for CNC Systems

SuperDry-M provides a stable, low-dew-point airflow directly at the point of use. Unlike bulky refrigerated dryers or maintenance-intensive desiccant systems, it requires no electricity, no regeneration cycle, and no downtime.

By installing compact SuperDry-M modules near CNC clusters, manufacturers can:

Eliminate water condensation in pneumatic valves and air bearings.

Protect cutting tools and spindles from oxidation.

Maintain dimensional stability in precision machining.

Reduce total operating costs through energy-free drying.

Image 2. Integration Example

Performance and Sizing Reference

*Purge ratio: 10–15 % depending on dew-point target and ambient conditions.

Comparing Drying Technologies

Conclusion

Whether ensuring perfect coating finishes or maintaining micron-level machining precision, dry compressed air is essential. The SuperDry-M membrane dryer delivers stable dew-point control, zero energy consumption, and virtually maintenance-free operation, making it the ideal solution for painting, coating, and CNC applications.

With SuperDry-M, PHILOS continues to advance efficient and sustainable compressed-air treatment, keeping productivity high and processes perfectly dry.

Find More Information

Find us on other social media platforms:

Comments